Our Bronze Process

What is the Bronze Casting process?

Adonis Bronze employs the Lost-wax process to help artists take their sculptures from clay, wood, or another medium and transition them into bronze. This process involves pouring molten metal into a heat proof mold that has been created by means of a wax model. This process was commonly used as far back as the 3rd millennium BC.

The Artist

The beginning of a new bronze sculpture generally starts with the Artist making a maquette.

They might have gotten a commission for a new piece, or decided on a neat new idea for something original.

After the maquette is made the piece will be remade in the final size.

Detail is added and refined until the piece is ready to be cast in bronze.

3D Imaging

They might have gotten a commission for a new piece, or decided on a neat new idea for something original.

After the maquette is made the piece will be remade in the final size.

Detail is added and refined until the piece is ready to be cast in bronze.

Mold Making

The mold process starts with the tech applying multiple rubber coats to the clay.

A large piece will also have to be sectioned into pieces in order to handle it practically.

When the rubber is thick enough a hard plaster shell is made to add rigidity and strength.

When pulled off the piece you can see a negative image of what was in the clay.

Wax Pour

Each piece of the mold then goes into Wax Pour, where melted wax is poured into the mold.

The wax completely coats the inside of the mold and the excess is removed.

After the wax has cooled the mold is removed and checked for quality.

The wax forms a new positive image of the original sculpture. The mold can then be reused for multiple reproductions.

Wax Chase

Each individual piece of wax is then checked over to make sure every detail from the original is present.

Each piece then needs sprues and a base cup added.

The sprues will act as pathways for the molten bronze to flow through later in the process.

It takes a lot of sprues to get a large piece ready to move on in the process.

Slurry

The wax is then dipped in a slurry mixture to start the creation of a shell that will withstand the heat of molten bronze.

It is then covered with a silicate sand and left to dry.

This will be repeated for five to six coats as needed to ensure the shell is thick enough.

The final coat adds the needed strength to the shell.

Metal Pour

The shells are then heated up to remove the wax from inside. This creates the next negative image.

They are then placed into a furnace and brought up to temperature.

Bronze melts at 1675 degrees fahrenheit. Special protective equipment is necessary.

The molten bronze is then poured into each individual shell.

Metal Chase

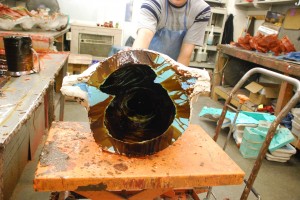

After the bronze cools the shell is removed and the piece can be seen.

All of the pieces are then brought together and a 3D puzzle begins.

The pieces are then welded back together and the piece is checked to ensure all the detail is still present.

The final positive image of our original sculpture is complete.

Patina

The piece is then moved into Patina where the coloration is added to the bronze according to what the artist desires.

The bronze material has chemicals applied to its surface.

Heat is then added to allow the pores of the bronze to accept the color.

After the final color is correct, wax is added to give the bronze a layer of protection.

The Piece is finished

The artists’ vision is then ready to be delivered.